Servoflo will be exhibiting at this year's Sensors Expo from June 26-28, 2018 in San Jose. We are pleased to offer free exhibit passes and $100 off the conference attendance to our customers and visitors (use code 232L when registering). Please see the information below on how to register. We will be there with all of our products!

Visit us at Booth 648!

Sensors Expo & Conference

Conference & Expo: June 26-28, 2018

Pre-Conference Symposia: June 25, 2018

McEnery Convention Center

San Jose, CA

www.sensorsexpo.com

Event Description

Sensors Expo & Conference is the only industry event in North America exclusively focused on sensors and sensor-integrated systems. For more than 30 years, Sensors Expo has brought technical innovation and thought leadership to engineers involved in the development and deployment of sensors and sensing systems. During this information packed, 3-day program, explore cutting-edge trends and applications through new products, technology pavilions, demos, and showcases of 300+ of the latest sensors. The featured technology displayed includes: Energy Harvesting & Power, Emerging Technologies, Flexible & Wearable Tech, IoT & Wireless, Measurement & Detection, MEMS & Sensors, Novel Sensor Applications, Optical Sensing & Detection, Sensors & Embedded Systems, and Sensor Data. New this year, the event will be co-located with the Medical Sensors Design Conference and an Autonomous Vehicle Sensors Conference. This educational, information-packed Sensors & Connectivity week provides the ideal place for technologists to find opportunities and engineers to innovate solutions.

Partnering with the factories we represent, Servoflo supports customers anywhere along the price/performance continuum from the most basic components to modified output sensors to completely customizable turnkey sensor solutions across a wide range of industries. Depending on the factory/partner, it could be possible to add a display unit, Wi-Fi, or Bluetooth capabilities. Or, adding flex to a sensor, creating packaging enclosures and custom flow paths, or integrating multiple parameters into a single sensor. It is worth the time and effort to ask: Who can best provide the required features: factory or customer?

Partnering with the factories we represent, Servoflo supports customers anywhere along the price/performance continuum from the most basic components to modified output sensors to completely customizable turnkey sensor solutions across a wide range of industries. Depending on the factory/partner, it could be possible to add a display unit, Wi-Fi, or Bluetooth capabilities. Or, adding flex to a sensor, creating packaging enclosures and custom flow paths, or integrating multiple parameters into a single sensor. It is worth the time and effort to ask: Who can best provide the required features: factory or customer? Creating a pressure gauge with display and enclosure

Creating a pressure gauge with display and enclosure

Payment terms are prepayment via check or credit card only. No performance guarantees or warranties are in effect. The pdf data sheet is in the model number link. The quantity available is subject to change without notice.

Payment terms are prepayment via check or credit card only. No performance guarantees or warranties are in effect. The pdf data sheet is in the model number link. The quantity available is subject to change without notice.

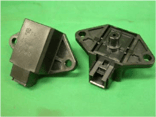

Unlike typical board mount pressure sensors, ceramic pressure sensors do need to be packaged. Our team of experts can assist you in designing the ideal package for your application. Furthermore, Servoflo offers a special evaluation mounting kit called MEKIT 0400 to help users test ceramic pressure sensors. This kit costs $145 and is useful for the following 18 mm diameter Metallux sensors: ME501/ME505/ME662/ME651/ME75X/ME77X/ME780.

Unlike typical board mount pressure sensors, ceramic pressure sensors do need to be packaged. Our team of experts can assist you in designing the ideal package for your application. Furthermore, Servoflo offers a special evaluation mounting kit called MEKIT 0400 to help users test ceramic pressure sensors. This kit costs $145 and is useful for the following 18 mm diameter Metallux sensors: ME501/ME505/ME662/ME651/ME75X/ME77X/ME780.

Servoflo is pleased to announce the FPWS Water Level Sensor. The FPWS is a gauge pressure sensor for -49 kPa to 68.5 kpa with a linear voltage output. The sensor is oil-filled for specific use in tank level measurement applications. Typical water exposure is tap water with or without bath or cleaning agents.

Servoflo is pleased to announce the FPWS Water Level Sensor. The FPWS is a gauge pressure sensor for -49 kPa to 68.5 kpa with a linear voltage output. The sensor is oil-filled for specific use in tank level measurement applications. Typical water exposure is tap water with or without bath or cleaning agents.

Servoflo, a premier supplier of pressure, mass flow, environmental sensors and micropumps, is pleased to announce expansion of its design engineering services for custom sensor development. The objective is to be a primary resource for customers who require modification or customization of sensors and how they are integrated into product designs. Services include but are not limited to:

Servoflo, a premier supplier of pressure, mass flow, environmental sensors and micropumps, is pleased to announce expansion of its design engineering services for custom sensor development. The objective is to be a primary resource for customers who require modification or customization of sensors and how they are integrated into product designs. Services include but are not limited to: This one-stop solution provides customers with efficient and reliable design expertise without having to manage multiple vendors as well as streamlining assembly. Purchasing a complete solution saves customers money and time. Often, a bill of materials is reviewed and pressure is put on individual component costs. This strategy neglects the labor needed to inspect, integrate, and test various separate components such as a sensor element, cable, and package. A complete sensor solution can actually reduce overall bill of materials and labor costs. This sensor design strategy is also important for customers who may not have design expertise in these areas.

This one-stop solution provides customers with efficient and reliable design expertise without having to manage multiple vendors as well as streamlining assembly. Purchasing a complete solution saves customers money and time. Often, a bill of materials is reviewed and pressure is put on individual component costs. This strategy neglects the labor needed to inspect, integrate, and test various separate components such as a sensor element, cable, and package. A complete sensor solution can actually reduce overall bill of materials and labor costs. This sensor design strategy is also important for customers who may not have design expertise in these areas.

At Sensors Expo, held this past June in San Jose, David Ezekiel gave a special show floor presentation titled

At Sensors Expo, held this past June in San Jose, David Ezekiel gave a special show floor presentation titled

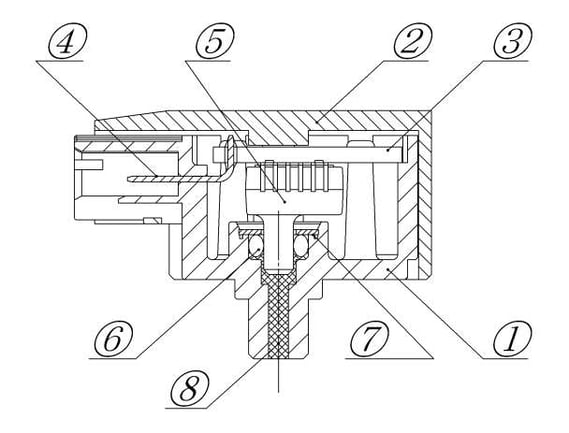

The following is a short synopsis of a new application note for the TR Series harsh media pressure sensor.

The following is a short synopsis of a new application note for the TR Series harsh media pressure sensor.