Today we have important news to share with you. After 34 years, Servoflo will discontinue its distribution business at the end of 2024. The global nature of our business has dictated that we seek a larger partner to serve our loyal customers who frequently design, source, and manufacture in all corners of the globe.

To that end, we will transition many customers to Angst+Pfister this year. Angst+Pfister (A+P) is an international distributor and manufacturer, headquartered in Zurich, Switzerland. They have a US division and lengthy experience with many of our factory partners in Europe. Our long-standing global relationship with A+P makes us confident you will be in good hands with them.

What does this mean for you, our cherished customer?

All current orders will be shipped as committed by Servoflo. Expediting is possible as long as our inventory can meet an earlier date. All orders remain non-cancellable and non-returnable. If we have an excess inventory of parts you have previously ordered, we can accept orders anytime. In principle, A+P will begin accepting orders in May 2024. For the next several months, we will work closely with A+P to ensure a smooth transition of key personnel and business practices. Those with blanket orders, please be assured we will work closely with you to ensure you receive all your deliveries and we will put you in touch with the appropriate contacts for future orders. We will handhold every customer during this transition.

A+P will become the North American representative for Fujikura, Sensormate, Metallux, Consensic, HYB, and Siargo. While our two companies will not overlap in order taking, Servoflo will support A+P and our customers during this critical transition. A+P is a large, worldwide organization with in-house technical experts in various sensor technologies, applications, and architectures. Angst+Pfister can be contacted via their email box info.apus@angst-pfister.com for any sample, quote, order, or technical information request. For all other factories not mentioned, you may contact them directly.

Our factory partners have been fully supportive of this transition as they see the potential of A+P to support you:

"Fujikura has worked with Angst & Pfister in Europe for over 30 years. We are pleased to extend our relationship to North America with the new U.S. division of Angst & Pfister. We are confident our customers will be in capable hands." - Jason Peng, President of Fujikura America, Inc.

“Metallux is grateful for Servoflo’s past work in North America, and we are looking forward to continuing our growth and presence with our new Angst & Pfister partnership. We are confident in their technical knowledge and professional expertise.” – Massimo Romano - General Manager, Metallux SA

“Sensormate is excited to be part of the Angst & Pfister team in North America" - Leo Wu, President of Sensormate Enterprise Co., Ltd.

If you have any questions or concerns, contact us at info@servoflo.com or reply to this email. You may also call our office at 781-862-9572.

We are eternally grateful and humbled to have been in this business for 34 years. We have enjoyed this journey and have been privileged to learn from our customers who design and manufacture the best products in their markets.

Sincerely,

David Ezekiel, Owner

david@servoflo.com

About Angst+Pfister

Angst+Pfister is a leading supplier of technical components and comprehensive solution provider for a wide range of industries and has been ensuring business continuity and serving the world’s leading manufacturers for over 100 years. Their professional capabilities center on being an engineering-led solution provider with in-depth customer application knowledge; globally sourcing a wide range of high-quality standard and customized industrial components; and proactively serving original equipment manufacturers (OEMs) around the globe through multiple sales channels.

Angst+Pfister North America Inc. | 10391 Brecksville Rd. | Brecksville, OH 44141 | USA

Phone +1 (440) 375-5212

![[eBook Cover] Pressure Sensor Selection Guide](https://blog.servoflo.com/hs-fs/hubfs/%5BeBook%20Cover%5D%20Pressure%20Sensor%20Selection%20Guide.png?width=152&name=%5BeBook%20Cover%5D%20Pressure%20Sensor%20Selection%20Guide.png)

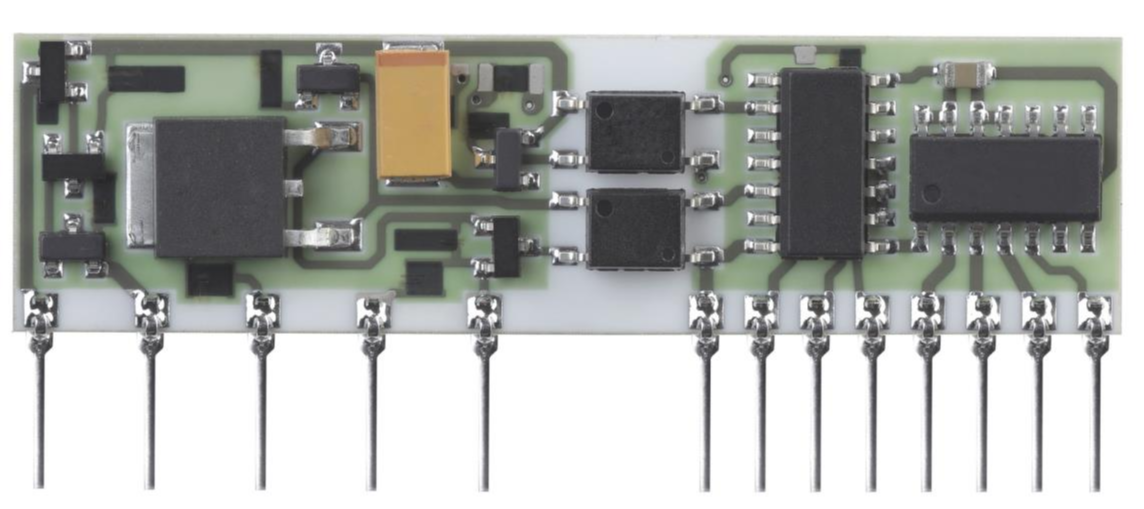

Production Equipment:

Production Equipment:

![[eBook Cover] Pressure Sensor Selection Guide](https://blog.servoflo.com/hs-fs/hubfs/%5BeBook%20Cover%5D%20Pressure%20Sensor%20Selection%20Guide.png?width=134&name=%5BeBook%20Cover%5D%20Pressure%20Sensor%20Selection%20Guide.png)

.jpg?width=240&name=image003%20(1).jpg)

.jpg?width=299&name=oxygen-concentrator-header%20(1).jpg)

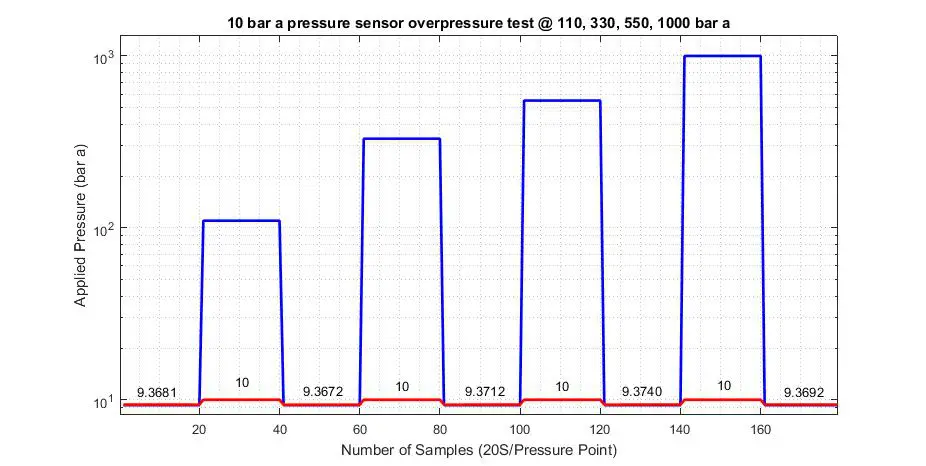

.jpg?width=240&name=infusion-pump-2%20(1).jpg) Our infusion pump pressure sensors meet a variety of pressure range demands. The sensors are temperature-compensated and have chips that provide data for smart

Our infusion pump pressure sensors meet a variety of pressure range demands. The sensors are temperature-compensated and have chips that provide data for smart