What Is a Humidity Sensor?

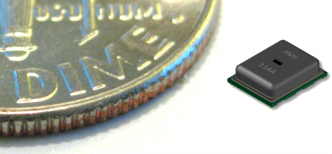

Humidity refers to the amount of water vapor present in the surrounding air. Humidity sensors are devices that measure moisture and air temperature in an environment and convert the data into a corresponding electrical signal. Modern humidity sensors are highly adaptable and come in many shapes and sizes, from miniature sensors installed in cell phones, to larger, industrial-grade systems.

Humidity refers to the amount of water vapor present in the surrounding air. Humidity sensors are devices that measure moisture and air temperature in an environment and convert the data into a corresponding electrical signal. Modern humidity sensors are highly adaptable and come in many shapes and sizes, from miniature sensors installed in cell phones, to larger, industrial-grade systems.

How Do Humidity Sensors Work?

Typically, humidity sensors contain a humidity sensing element and a thermistor, which is used to measure temperature. There are three main types of humidity sensors, each of which monitors small changes in the atmosphere to calculate humidity. These types include:

- Capacitive. Capacitive humidity sensors are linear and measure relative humidity from 0% humidity to 100% humidity. They do this by placing a small metal oxide strip between two electrodes. As the level of humidity changes, the oxide's electrical capacity changes along with it.

- Resistive. Resistive humidity sensors measure humidity through the use of ionized salts between two electrodes. The ions in the salts measure the electrical impedance of atoms. As humidity levels change, so does the resistance of the electrodes.

- Thermal. A thermal sensor utilizes a dual sensor system to measure humidity. One thermal sensor is housed in a layer of dry nitrogen; the other freely measures ambient air. The resulting difference between the two measurements represents the level of moisture in the air.

Humidity Sensor Applications

Humidity sensors are used across several industries to protect equipment and ensure safe and comfortable environments. Common applications include:

- Meteorology. Meteorological departments rely on humidity sensors to gauge accurate weather conditions in their respective areas.

- Medical. Many lifesaving medical devices rely on humidity sensors to regulate moisture. Ventilators, incubators, sterilization equipment, and more require careful moisture regulation to ensure safe and sterile function.

- Automotive. Vehicles use humidity sensors for purposes such as air intake in the engine and climate control inside the vehicle.

- HVAC. Humidity sensors are critical to climate control functions found in residential, commercial, and industrial HVAC systems.

- Manufacturing. Manufacturing equipment for food processing, textiles, paper, and more require humidity sensors to control the amount of moisture in the air and ensure the quality of their finished products.

Aside from those listed above, other industries that rely on humidity sensors include pharmaceutical, agriculture, electronics, and more.

Humidity Sensors from Servoflo

Humidity sensors measure the amount of moisture in the air to regulate environmental conditions for a variety of industries. At Servoflo, we offer a wide range of relative humidity sensors, humidity indicators, and humidity sensing elements designed for use in various applications. For more information, or to find out which humidity sensor is right for your needs, contact us today.

Moisture exists naturally in industrial gases and the surrounding environment. Within controlled industrial settings, industry professionals generally consider this moisture as an undesirable contaminant as it significantly impacts the quality and consistency of a process. If left unchecked, excess moisture causes condensation, corrosion, and contamination, which may result in:

Moisture exists naturally in industrial gases and the surrounding environment. Within controlled industrial settings, industry professionals generally consider this moisture as an undesirable contaminant as it significantly impacts the quality and consistency of a process. If left unchecked, excess moisture causes condensation, corrosion, and contamination, which may result in:

Sensor technology has changed dramatically over the past few years. Previously, customers purchased the sensor elements and electronics and calibrated a sensor themselves. The development of improved electronics, MEMs technology and efficient manufacturing technology has created a new humidity sensor market - fully calibrated humidity sensors with an I2C output. Many companies are offering models with similar features.

Sensor technology has changed dramatically over the past few years. Previously, customers purchased the sensor elements and electronics and calibrated a sensor themselves. The development of improved electronics, MEMs technology and efficient manufacturing technology has created a new humidity sensor market - fully calibrated humidity sensors with an I2C output. Many companies are offering models with similar features.

Recently an article was published in Design News about digital humidity sensors offered by Servoflo.

Recently an article was published in Design News about digital humidity sensors offered by Servoflo.