Servoflo is pleased to announce the FSP1000 Ultra Low Pressure Sensor. This sensor is designed to measure ±1" H2O up to ±2" H2O. With a compensated temperature range of -5°C to 65°C, the FSP1000 has a fast response time of 5 milliseconds and has an I2C with 12 bit resolution and linear voltage output of 0.4 to 2.4V. The supply voltage is 3.0 - 3.6 VDC.

Servoflo is pleased to announce the FSP1000 Ultra Low Pressure Sensor. This sensor is designed to measure ±1" H2O up to ±2" H2O. With a compensated temperature range of -5°C to 65°C, the FSP1000 has a fast response time of 5 milliseconds and has an I2C with 12 bit resolution and linear voltage output of 0.4 to 2.4V. The supply voltage is 3.0 - 3.6 VDC. Servoflo is pleased to announce the FSP1000 Ultra Low Pressure Sensor. This sensor is designed to measure ±1" H2O up to ±2" H2O. With a compensated temperature range of -5°C to 65°C, the FSP1000 has a fast response time of 5 milliseconds and has an I2C with 12 bit resolution and linear voltage output of 0.4 to 2.4V. The supply voltage is 3.0 - 3.6 VDC.

Servoflo is pleased to announce the FSP1000 Ultra Low Pressure Sensor. This sensor is designed to measure ±1" H2O up to ±2" H2O. With a compensated temperature range of -5°C to 65°C, the FSP1000 has a fast response time of 5 milliseconds and has an I2C with 12 bit resolution and linear voltage output of 0.4 to 2.4V. The supply voltage is 3.0 - 3.6 VDC.Topics: Pressure Sensors

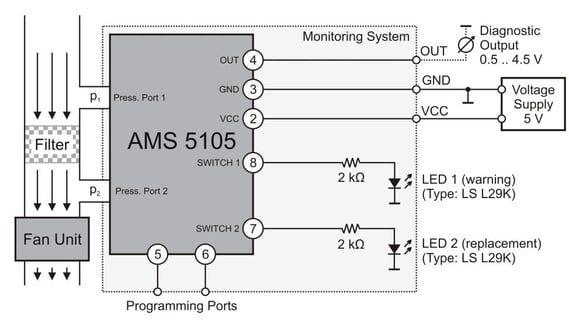

Monitoring HVAC Filter & Fan Units With AMS5105 Pressure Sensors

Analog Microelectronics has an application note discussing how to monitor HVAC fan and filter performance using the AMS5105 pressure sensor. The AMS5105 is a board-mount, compensated and calibrated pressure sensor with an analog ratiometric 0.5 to 4.5V output along with two discrete, programmable logic switching ports. For each switching port, the switching function, threshold, hysteresis and delay can be set individually. Having low differential pressure calibration from 100 mbar down to 5 mbar, the AMS5105 is ideal for fan and filter monitoring systems.

Analog Microelectronics has an application note discussing how to monitor HVAC fan and filter performance using the AMS5105 pressure sensor. The AMS5105 is a board-mount, compensated and calibrated pressure sensor with an analog ratiometric 0.5 to 4.5V output along with two discrete, programmable logic switching ports. For each switching port, the switching function, threshold, hysteresis and delay can be set individually. Having low differential pressure calibration from 100 mbar down to 5 mbar, the AMS5105 is ideal for fan and filter monitoring systems.

Included with the application note are the following four application examples with circuit drawings :

- Simple HVAC Filter Monitoring System With Pre-Warning - Here the switching ports are programmed as normally-open and hysteresis is set to 5% of the calibrated pressure range.

- HVAC Filter Monitoring System with a 24V Supply and Robust Outputs - Similar to the first example but includes details what to do if only 24VDC is available as a supply.

- HVAC Filter and Fan Monitoring System With Diagnostics - Learn how to set up the switching ports for normal and filter replacement

- HVAC Monitoring System with Diagnostics Measured at an Orifice - Similar to #2 but measurement is taken across an orifice to protect the sensor from contaminants.

Here is the circuit drawing for item #1, Simple HVAC Filter Monitoring System With Pre-Warning:

As you can see, this application note gives great details on how to use the AMS5105 for HVAC filter monitoring. We hope you find it as a useful tool that can be applied across many different applications.

Download the complete application note

Topics: Pressure Sensors

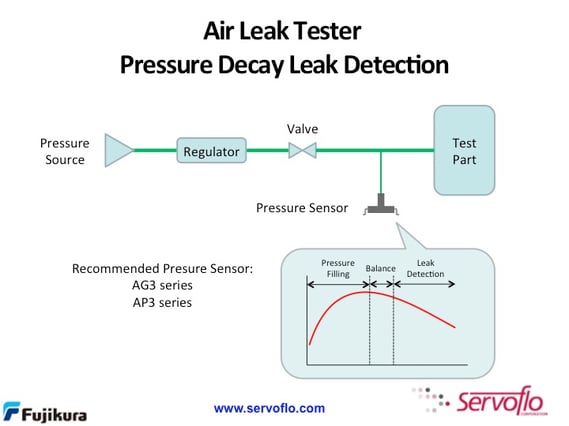

Different methodologies exist for creating leak detection systems. In this blog post, we will focus on leak detection using a pressure decay method which is ideal for detecting very small leak rates.

The diagram below illustrates a classic leak detection setup using pressure decay.

The test part is pressurized from a pressure source. At the first X under "Balance" in the chart above, the pressure setpoint is reached and balance is maintained until the leak detection test begins at the second X. The regulator and valve isolate the test part from the source once pressurization is complete. The pressure sensor monitors and measures the pressurized test part. If the pressure measurement decreases, then air is leaking out of the test part. Measuring the change in pressure over a period of time allows the user to calculate the leak rate.

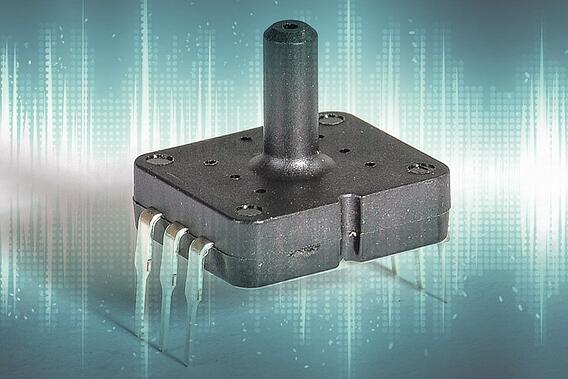

The availability of easy-to-use, sensitive pressure sensors at low cost lets designers optimize their leak detection design. The AP3/AG3 Series is an example of a pressure sensor well-suited for leak detection applications. The AP3/AG3 is a calibrated and temperature-compensated pressure sensor with ranges from 0-25 kPa up to 0-1000 kPa. Not only does this sensor have high accuracy of ±1.5% full-scale, the AP3/AG3 has built-in threshold detection (consider how easy it is to set the threshold for the start of the leak test). The AP version has a dual-in-line package while the AG version is surface-mount. With a price of of approximately $7 (depending on the model) at 1,000 pieces, the AP3/AG3 provides has an excellent price-performance ratio.

The availability of easy-to-use, sensitive pressure sensors at low cost lets designers optimize their leak detection design. The AP3/AG3 Series is an example of a pressure sensor well-suited for leak detection applications. The AP3/AG3 is a calibrated and temperature-compensated pressure sensor with ranges from 0-25 kPa up to 0-1000 kPa. Not only does this sensor have high accuracy of ±1.5% full-scale, the AP3/AG3 has built-in threshold detection (consider how easy it is to set the threshold for the start of the leak test). The AP version has a dual-in-line package while the AG version is surface-mount. With a price of of approximately $7 (depending on the model) at 1,000 pieces, the AP3/AG3 provides has an excellent price-performance ratio.

Applications for leak detection include:

- Medical devices such as drug delivery, catheters, valve, oxygen delivery

- HVAC including refridgerant testing, heat exchangers, tubing, radiators, and more

- Automotive testing such as emission systems, fuels, pumps, and cooling systems

- Various industrial applications

Learn more about the AP3/AG3 or

Topics: Pressure Sensors

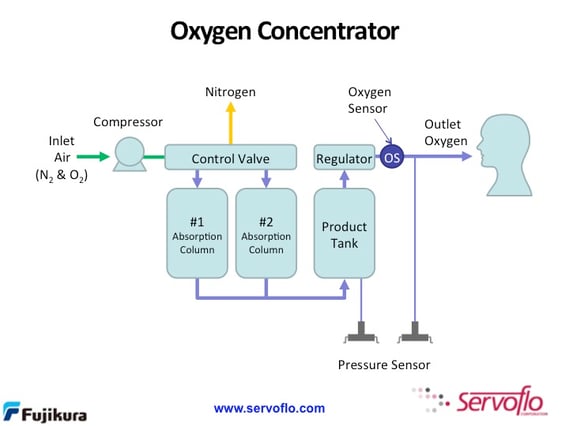

Pressure & Oxygen Sensors in Oxygen Concentrators

An oxygen concentrator is a medical device to deliver oxygen to a patient. A typical concentrator consists of a compressor, absorption columns with air filters, circuitry, a product tank and regulator. Oxygen concentrators differ from machines delivering compressed oxygen from tanks filled at a separate location. Instead, an oxygen concentrator takes standard room air, filters out the nitrogen and other gases, leaving oxygen to be delivered to the patient.

The block diagram shows a design of a typical oxygen concentrator. Pressure and oxygen sensors are used at various points to ensure proper creation and delivery of oxygen. For example, a pressure sensor is used at the product tank to measure the tank's level and to ensure there is proper flow moving into the regulator.

Often times there is also a pressure sensor between the regulator and outlet oxygen. A stationary oxygen concentrator may use a pressure sensor in the 50 kPa r ange to detect a kink in the tubing. (See AP2/AG2 analog pressure sensor or AP3/AG3 pressure sensor with threshold detection). For portable oxygen concentrators, a pressure sensor in the 1 kPa range is used to detect inhalation which then controls the regulator. Here, it is important to use a pressure sensor that is sensitive enough to detect the low flow rate of breathing but can also withstand high overpressures. The AL4 is a good option meeting this requirement.

ange to detect a kink in the tubing. (See AP2/AG2 analog pressure sensor or AP3/AG3 pressure sensor with threshold detection). For portable oxygen concentrators, a pressure sensor in the 1 kPa range is used to detect inhalation which then controls the regulator. Here, it is important to use a pressure sensor that is sensitive enough to detect the low flow rate of breathing but can also withstand high overpressures. The AL4 is a good option meeting this requirement.

Finally, and perhaps most obviously, an oxygen sensor can be installed to sense the oxygen percentage of the air being delivered to the patient. The oxygen sensor allows the designer to create alarms and set points for the filtering portion of the concentrator.

Finally, and perhaps most obviously, an oxygen sensor can be installed to sense the oxygen percentage of the air being delivered to the patient. The oxygen sensor allows the designer to create alarms and set points for the filtering portion of the concentrator.

The abundance of sensing technology has allows for the development of more flexible medical equipment with more features and functionality. This description of oxygen concentrators is one example of where the evolution of technology has created better health for all.

Topics: Pressure Sensors, Oxygen Sensors

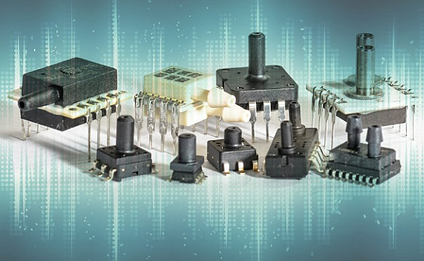

Continuous improvement in MEMS pressure die has allowed for the development of ultra low pressure sensors in small packages. Fully calibrated and compensated, these pressure sensors can measure as low as 0.07 psi (5 mbar), and come in gauge or differential packages with an I2C output.

Continuous improvement in MEMS pressure die has allowed for the development of ultra low pressure sensors in small packages. Fully calibrated and compensated, these pressure sensors can measure as low as 0.07 psi (5 mbar), and come in gauge or differential packages with an I2C output.

Previous solutions for measuring low pressure include large, bulky packages that are high in cost, large in size, and a cost prohibitive price for high volume applications. This new generation of ultra low pressure sensors provides the following key advantages:

- High working and burst pressures

- Long-term stability over time

- Wide temperature compensation

- Simplified system calibration

- Interchangeability of sensors

- Low voltage supply

- Insensitive to mounting orientation

These important features have opened up new applications in many areas, including:

- Medical - respirators, sleep apnea, and more

- HVAC - VAV controls, portable devices, and critical containment such as cleanrooms, fume hoods and biological safety cabinets

- Pneumatic devices and other industrial controls

- Consumer applications

- Transducer development

Here are some examples of ultra low pressure sensors now available.

SM9543 - Differential pressure sensor wtih ranges as low as±0.07 psi (±5 mbar), I2C interface, 3 - 3.6V power supply, accuracy of ±1.5% full-scale. JEDEC SOIC-16 package (about 10 mm x 10 mm). Temperature compensated from -5°C to +65°C. Burst pressure of 3 psi.

SM9543 - Differential pressure sensor wtih ranges as low as±0.07 psi (±5 mbar), I2C interface, 3 - 3.6V power supply, accuracy of ±1.5% full-scale. JEDEC SOIC-16 package (about 10 mm x 10 mm). Temperature compensated from -5°C to +65°C. Burst pressure of 3 psi.

SM9541 - Similar to SM9543 with slightly higher pressure ranges from 0.14 psi up to 2 psi. Gauge and differential available. Burst pressure varies with calibration range from 3 psi up to 15 psi.

AL4 - Gauge pressure sensor for 0-20 mbar (0-2 kPa) up to 100 mbar (10 kPa). I2C interface, supply voltage options of 3V, 3.3V, 5V.±1.5% accuracy. High load pressure of 100 kPa. Size of 11.36 mm x 10.32 mm. Modified calibration ranges available.

AL4 - Gauge pressure sensor for 0-20 mbar (0-2 kPa) up to 100 mbar (10 kPa). I2C interface, supply voltage options of 3V, 3.3V, 5V.±1.5% accuracy. High load pressure of 100 kPa. Size of 11.36 mm x 10.32 mm. Modified calibration ranges available.

See all low pressure sensors offered by Servoflo.

Topics: Pressure Sensors

Ceramic pressure sensors by Metallux of Switzerland are high quality, high performing sensors for harsh environments and/or higher pressures (models up to 800 bar). With various models including piezo-resistive, ceramic capacitive, monolithic, flush-mount, compensated, unamplified and more, a user reviewing ceramic pressure sensors may want some help understanding the various options.

Ceramic pressure sensors by Metallux of Switzerland are high quality, high performing sensors for harsh environments and/or higher pressures (models up to 800 bar). With various models including piezo-resistive, ceramic capacitive, monolithic, flush-mount, compensated, unamplified and more, a user reviewing ceramic pressure sensors may want some help understanding the various options.

Piezo-Resistive Versus Capacitive: At a high level, Metallux ceramic pressure sensors are either piezo-resistive or capacitive pressure sensors. Why choose one over the other? Capacitive sensors are used when the pressure sensors must withstand high overpressures. In addition, capacitive models such as the ME550 (shown right) are very good at measuring low pressure down to 60 mbar. Both capacitive and piezo-resistive have similar chemical resistance and media compatibility.

Flush Mount Versus Monolithic: In a flush mount sensor such as the ME77X Series, the sensor side exposed to the pressure media is flat and smooth. A monolithic sensor such as the ME75X has an indentation in the center of the exposed side. Why choose one or the other? If a customer is making an absolute or sealed gauge sensor, then flush mount is ideal as they have a fixed reference. Flush mount also come in lower (0.5 bar) and higher pressures (up to 600 bar). Flush mount ceramic sensors also have no dead volume of the pressure media.

Flush Mount Versus Monolithic: In a flush mount sensor such as the ME77X Series, the sensor side exposed to the pressure media is flat and smooth. A monolithic sensor such as the ME75X has an indentation in the center of the exposed side. Why choose one or the other? If a customer is making an absolute or sealed gauge sensor, then flush mount is ideal as they have a fixed reference. Flush mount also come in lower (0.5 bar) and higher pressures (up to 600 bar). Flush mount ceramic sensors also have no dead volume of the pressure media.

Amplified or Unamplified: Another choice in ceramic pressure sensors involves whether or not to choose an amplified, calibrated sensor (ME75X, ME78X, ME790) or an unamplified model (ME501, ME504, etc). The choice depends on the users' requirements. For customers who do not have the capacity to amplify the signal and wanted a completely calibrated and temperature compensated sensor, Metallux offers many models with either a ratiometric, non-ratiometric, current loop, or I2C. The integrated signal conditioning lets users start using the sensors quickly. A user who is perhaps designing their own transducer will likely consider purchasing an unamplified model. Then, these users who typically have the experienced needed, can create a customized signal conditioning design based on their specific application requirements.

Physical Size: Not all Metallux ceramic pressure sensors are the same size! The largest is the ME509 at 32.4 mm in diameter. The smallest is me ME657 at 12.85 mm in diameter. Many models are 18 mm in diameter.

Ceramic pressure sensors are a great choice if you are looking for higher pressures (up to 800 bar) in a harsh or wet environment. Gauge, sealed gauge and absolute models are also available. Strong chemical resistance due to the user of the AI2O3 ceramic lets users expose the sensors to a wide variety of environmental factors. Typical applications for Metallux ceramic pressure sensors include transducer development, tank level monitoring, process control and industrial automation.

We hope you found this blog post to be useful! Please feel free to reach out to us at info@servoflo.com with questions or comments. We welcome your feedback.

Download the metallux-family-tree here.

Topics: Ceramic Pressure Sensors, Pressure Sensors

Why Choose Fujikura Pressure Sensors Over Freescale?

In the world of pressure sensors, users have a broad range of manufacturers and part numbers to choose from. Although detailed specifications on individual parts are easy to come by, we thought it would be nice to provide a comparison between the new AP/AG pressure sensors from Fujikura to various Freescale sensors, including the MPXV7025, MP3V5050(V)/MPX(V)5050(v), MPX(V)5100, and MPX5500. The following summary provides details on how Fujikura pressure sensors offer higher performance and more flexibility for users.

In the world of pressure sensors, users have a broad range of manufacturers and part numbers to choose from. Although detailed specifications on individual parts are easy to come by, we thought it would be nice to provide a comparison between the new AP/AG pressure sensors from Fujikura to various Freescale sensors, including the MPXV7025, MP3V5050(V)/MPX(V)5050(v), MPX(V)5100, and MPX5500. The following summary provides details on how Fujikura pressure sensors offer higher performance and more flexibility for users.

- More input voltage flexibility: All Fujikura AP/AG sensors come in a 3V, 3.3V or 5V supply. The Freescale sensors models listed above come in some but not all supply voltages.

- Pressure range choices: With a broad selection of ranges from +/-100 kPa up to 1000 kPa, Fujikura offers many more choices.

- Customization: In addition, Fujikura is willing to offer custom calibration and custom outputs in quantities that are normally too small for other manufacturers.

- Accuracy: Fujikura offers +/-1.5% full scale accuracy versus +/-2.5% or +/-5% for Freescale pressure sensors.

- Additional models with threshold detection (AP3/AG3) or digital outputs (AP4/AG4)

- Lower supply current: Freescale sensors require a 10 mA supply current. Fujikura, on the other hand, has a supply current of 3 mA for the 5V supply and 2 mA for the 3V and 3.3V supply versions.

Fujikura's stocking distributor (yes, Servoflo) has over 30 years experience selling and providing technical support for Fujikura pressure sensors.

Typical applications for these parts include sleep apnea, oxygen conservers, blood pressure measurement, ventilators, industrial applications and more.

Our experience over the last 30 years selling Fujikura have shown that these pressure sensors are high quality yet cost-effective for customers. The ability to easily customize sensors for customers' specific needs is a powerful consideration when comparing pressure sensors. We are proud of our relationship with Fujikura and look forward to showing you why!

Quick links:

- AP2/AG2 - analog output

- AP3/AG3 - analog output with threshold detection

- AP4/AG4 - digital output

- Fujikura/Freescale comparison chart

- Fujikura AP/AG pressure sensor overview

Topics: Pressure Sensors

Why We Do Not Take Online Orders for Pressure Sensors

On our Servoflo website, you have likely noticed limited online ordering of pressure sensors. Even though we have a huge offering of pressure sensors from 0.1” to several thousand psi, there are specific reasons why we do not have an online store and parametric search for sensors.

Complexity of pressure sensor part numbers – Have you ever searched for a sensor and become completely overwhelmed figuring out the correct part number to order? Have you ever ordered a part and then realized after your purchase you made a mistake, and then had to order a different part?

Stock – have you had difficulty finding stock of a particular part, and then spent an afternoon browsing, clicking, and sorting through part numbers and manufacturers?

In short, trying to buy pressure sensors online can be a time consuming, frustrating experience. The sheer combination of permutations and combinations of part numbers make for nightmare scenarios for both purchasers and webmasters.

OK, so now after spending an afternoon browsing you may be completely confused by what you saw where. Now that you have come across various pressure sensors options (such as amplified versus unamplified), you may be wondering, what type of pressure sensor do I really need? What does this accuracy spec mean on this datasheet versus this accuracy spec from a different manufacturer? I need a specific package but I don’t see it…Let us show you how to get you out of this mess.

Just the other day, we received a telephone call from a potential customer. After 30 seconds of listening to the customer explain his application, David Ezekiel, our Vice President said, “I know exactly what you need, let me send you the detailed part information.” The customer was very appreciative and thankful for being put in the right direction. We knew how to answer his question because we had experience in his application combined with our vast knowledge of pressure sensors.

So, after you “Google” to find a pressure sensor supplier the next step is to “Servoflo it!”. Find the right sensor for YOUR application quickly and easily by either calling us at 781-862-9572 or emailing your specification through our sensor selector tool.

Topics: Pressure Sensors

UPDATE! Here is a short video clip of our booth and the products we showed! Thanks to Randy Frank at Design World for the video.

From June 25 to June 26, 2014, Servoflo exhibited at the Sensors Expo show in Chicago. We had a great time and thought it would be fun to share a couple of pictures of our booth.

The show was well attended, and booth traffic was busy on both days. We met many new customers interested in a wide variety of our products. Applications ranged from industrial, consumer, medical and more. It was interesting to see how many people traveled to come to the show, which also had many educational sessions.

We enjoyed exhibiting next to our supplier ZMDI (a supplier of signal conditioning IC's, LED drivers, and power management IC's). Their special pink popcorn giveaway was very popular with booth visitors.

We hope to see you at next year's Sensors Show which will be held June 9 - 11 in Long Beach, California.

You can check out the official Sensors Expo highlights reel here.

(Above image is David Ezekiel of Servoflo providing visitors with sensing solutions!)

Topics: Sensors Expo, Pressure Sensors