Oxygen measurement is critical in a wide range of applications. From ensuring enough oxygen exists for life sustainability and development, to monitoring harmful and dangerous gases, oxygen sensing can be found in medical equipment, HVAC systems, industrial processing, instrumentation, and the new exciting field of additive layer manufacturing with metals and alloys.

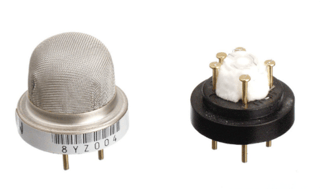

The oxygen sensors offered by Servoflo are a zirconium-based sensor. The sensing element is heated to more than 350°C which allows oxygen molecules to penetrate the sensing chamber. A voltage is applied to pump the oxygen out of the chamber. The measurement current produced is proportional to the quantity of oxygen molecules pumped away.

The oxygen sensors offered by Servoflo are a zirconium-based sensor. The sensing element is heated to more than 350°C which allows oxygen molecules to penetrate the sensing chamber. A voltage is applied to pump the oxygen out of the chamber. The measurement current produced is proportional to the quantity of oxygen molecules pumped away.

Key advantages of the zirconium-based approach include:

- Long-term stability with minimal drift

- The operating lifetime of the sensor is greater than 4 years

- Temperature operation up to 300°C

- Ambient pressure has no effect on oxygen measurement, eliminating the need for pressure compensation

Stand-alone oxygen sensors with a raw signal output are available. Users have to take the sensor signal and provide compensation and amplification. Alternatively, Servoflo is offering signal conditioned sensor modules with either an analog or digital signal output, the FXC-MLxx or FCX-MCxx Series.

The FXC-ML or FXC-MC has the following features:

- Can be configured for flow (force air into the sensor) or diffusion operation (sitting open-ended)

- Configurable for analog output or digital output

- Sensor head and connecting cable can be configured for 200°C

- Measurement ranges include 0.1-25% and 0.2-95% O2

- Accuracy of ±0.5% FS

- High quality Swiss manufacturing

- Standard off the shelf modules can be easily customized to meet your specific requirements

| FCX-MLxx | FCX-MCxx |

| 0.1 to 25% O2 | 0.1 to 25% or .2 to 95% O2 |

| 24VDC supply | 24VDC Supply |

| 4-20 mA output (logarithmic) | Linear analog of 0-10V, 0-20 mA, 4-20 mA included. Digital outputs available. |

| Learn more about FXC-MLxx | Learn more about the FCX-MCxx |

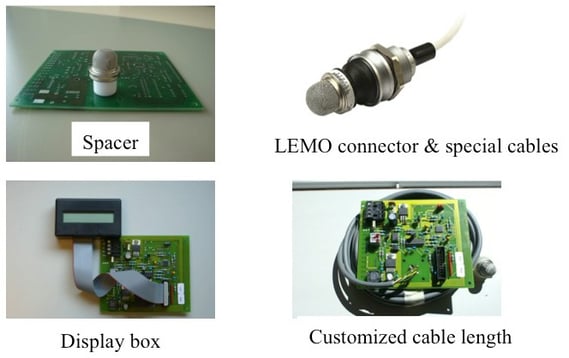

A wonderful aspect of these products is the ability for customization of many features. Here are some examples of customized versions of the FCX-ML/MC oxygen sensor modules:

CO2 incubators/cell culturing: The customer required I2C only for an output, and a sensor head to withstand 200°C while the cable and sensor head connector needed to withstand 180°C.

Critical containment and ventilated small animal enclosures: A customer required an RS485 output with DIN41612 for rack mounting.

Additive layer manufacturing with metals and alloys: 3D printing with metals and alloys is a new, growing field. The quality of the finished part is directly proportional to the oxygen concentration (the lower the better, ideally >1%). Special cable terminations were provided to prevent EMC issues.

Additional examples of customization are shown in the image below.

Should I use the oxygen sensor element only or buy a packaged solution? The answer is, it depends. A packaged solution such as the FCX-ML or MC is great for users who need to find a quick solution to evaluate the oxygen sensor without having to create electronics and circuitry. If a user has in-house expertise to compensate the raw signal, provide the electronics and desired packaging, then purchasing the sensor alone is a viable option. The packaged solution is great for those with limited resources to develop electronics and need help with packaging and design. Here, you can let Servoflo solve your sensor integration issues for you.