In many applications and industries, it is not uncommon to come across the risk of excessive pressure, or overpressure, within the pneumatic or hydraulic network of equipment, especially in facilities with a high degree of automation. If this phenomenon is not controlled properly, it may cause permanent damage to equipment and production lines which is why pressure sensors are commonly used as some form of protection in several operations such as industrial, medical, bioprocessing, and pharmaceutical.

Nevertheless, pressure transducers are not always able to handle extreme levels of pressure. In order to survive extreme pressures, engineers and designers have defined pressure ratings that can describe the conditions a pressure component can withstand without affecting its operational performance. These are divided into:

Nevertheless, pressure transducers are not always able to handle extreme levels of pressure. In order to survive extreme pressures, engineers and designers have defined pressure ratings that can describe the conditions a pressure component can withstand without affecting its operational performance. These are divided into:

-

-

-

-

-

- rated pressure

- overpressure

- burst pressure

-

-

-

-

The maximum pressure that the manufacturer assigns as the desired pressure at which a device will function properly is normally outlined as rated pressure. An overpressure value is a condition where the pressure transducer can withstand excessive pressure without affecting performance or compromising subsequent measurements. Often overpressure is mistaken for burst pressure, which is defined as the maximum pressure that can be applied without physically damaging the body of the sensing component.

For example, if a pressure sensor has 2 bar rated pressure, 5x overpressure, and 10x burst pressure, this means that the sensor can measure pressures up to 2 bar, it can withstand overpressures up to 10 bar without being damaged, and if the pressure reaches 20 bar the sensor sealing will burst. From 10 to 20 bar, the sensor does not burst but it is damaged and will not operate as expected.

What can cause overpressure?

Different factors can trigger overpressure, including unintentionally increased heat, uplift, a faulty pressure regulator, process synchronization, or an amalgamation of all these factors. These causes are common in industrial applications where there are solenoids, centrifugal pumps, regulators and valves.

How capacitive sensors can prevent catastrophic failures due to overpressure

Due to their design and measurement principle, MEMS capacitive pressure sensors can handle up to 100x overpressure, making them the only available sensor technology in the market that can withstand high overpressure.

The overpressure tolerance along with the excellent accuracy and total error band specification make capacitive sensors ideal for any application that uses pumps or valves, especially in automation equipment, where overpressure is frequently experienced.

Before selecting a sensor, the maximum pressure value needed for the application should be taken into consideration. Understanding the advantages of each technology, the dynamics of their system, the limits of the sensor, and the various ways it can be applied are important to increase productivity and lower maintenance costs.

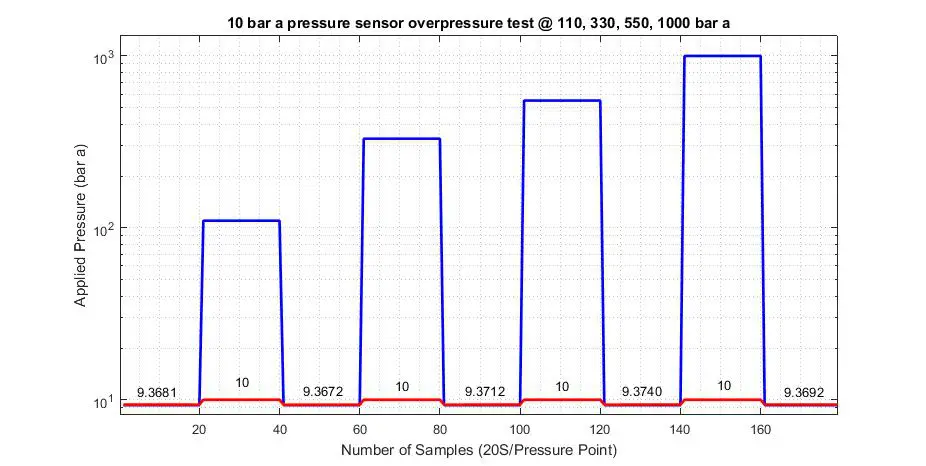

In the following figure, you can see an application example of the overpressure performance of a 10 bar absolute calibrated sensor from ES Systems. The sensor's maximum expected operating pressure (MEOP) is 10 bar. The sensor is measured at a reference pressure of 9.3 bar absolute and then pressurized at the following pressure steps as seen in the graph below.

As predicted, the sensor returns to nominal performance even with 100x overpressure is applied for a long period of time.