Metallux of Switzerland is expanding its offering of electronic manufacturing services. These state-of-the-art manufacturing and engineering services help customers get to market quickly. Reliability and flexibility allows Metallux to engineer, prototype, and produce over 4.5 million products every year.

Services include:

| Electronic assembly & manufacturing | Encapsulation & coating on various substrates |

| Reliable hybrid circuits | Finishing & injection with coatings, epoxy, silicon, resins |

| Multi-layered hybrid circuits with integrated components | Automated inspection & testing |

| Automated & manual screenprinting lines | Climatic chambers for calibration |

| Laser trimming |

X-ray & AOI testing |

| SMD, chip-on-board & reflow line | EMC compliance testing |

| Active & passive SMT, from 0402 to BGA and μBGA | End-of-life & test equipment for QA |

| Chip & wire: die attach, wedge & ball bonding | Production, assembly & packaging in a DNA-free environment |

To help better understand the capabilities available, here is a Q&A about these Metallux services.

What experience does Metallux have with power hybrids?

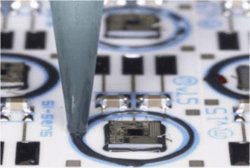

Metallux has long-term knowledge about chip & wire processes to interconnect bare chips to several types of different substrates by wedge & ball bonding. In the last two years, Metallux technicians attended several courses and learned relevant information about recent developments in the same processes for power dies.

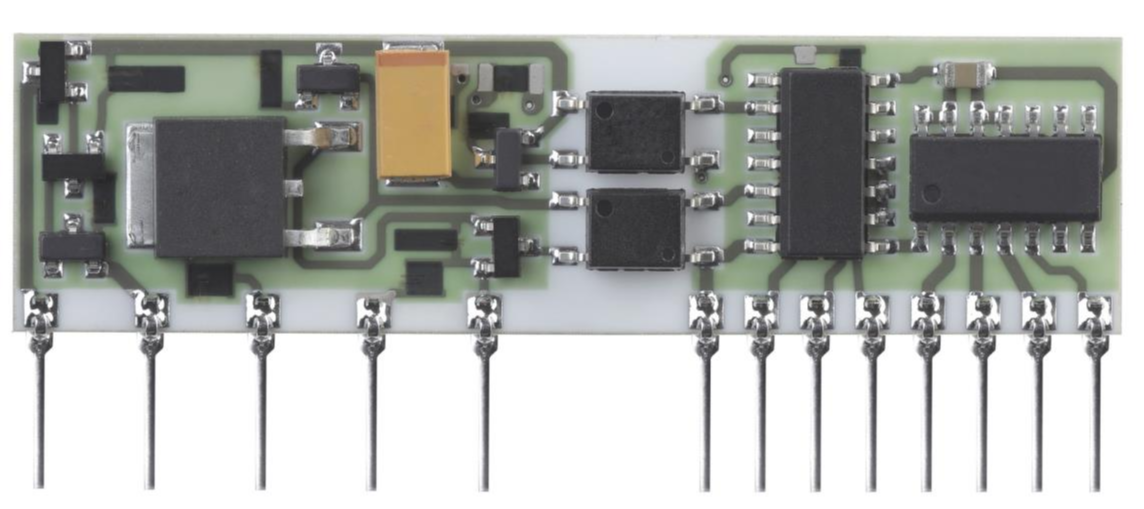

What technologies and processes does Metallux have for the production of power hybrids and what investments are needed to produce them?

Metallux has many years of experience in screen printing on ceramic (alumina) and metal (steel) substrates, soldering, and various wire bonding techniques including standard hybrid technology (A12O3), thick film technology, die-bonding, standard wire bonding, and more. We have invested heavily in any additional processes and equipment necessary for power modules and expect to be able to produce samples in 2023. The same equipment can also be used for producing several tens of thousands of power devices.

What kind of information does Metallux need from the customer to provide samples?

Standard information such as application details, technical specifications, environmental situations, commercial (price target, quantities, desired production schedule), specific technology required, and reason for inquiry. For example, if there already is an existing supplier, what are the current stumbling blocks? In addition, we would also need a BOM, schematics, dimensions, operating temperature range, operating voltage, operating current, and power dissipation.

Learn more about hybrid circuit & power module manufacturing from Metallux.