This is a guest blog post reproduced with permission from ES Systems, a specialist in high quality pressure sensors for a variety of applications.

The majority of the pressure sensors currently installed in the field are based on MEMS technology and utilize either piezoresistive or capacitive measurement principle. In this article, we will be discussing their main differences and we will be highlighting the advantages of each.

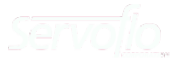

How Piezoresistive Technology Works

The term piezoresistive is composed by the Greek word “piezo” (meaning squeeze or press) and resist. In piezoresistive sensors, four resistors are placed on a silicon diaphragm in order to measure the result of strain or physical pressure applied upon them. Any perceptible change in resistance is being converted, through a Wheatstone bridge circuit into an output voltage. The piezoresistive pressure measurement principle is one of the firstly developed in MEMS technology and it was developed many years before the capacitive one. As a result, it is most commonly used. Due to their widespread and low production cost, piezoresistive pressure sensors are widely used in consumer electronics and the automotive industry, as well as in household appliances.

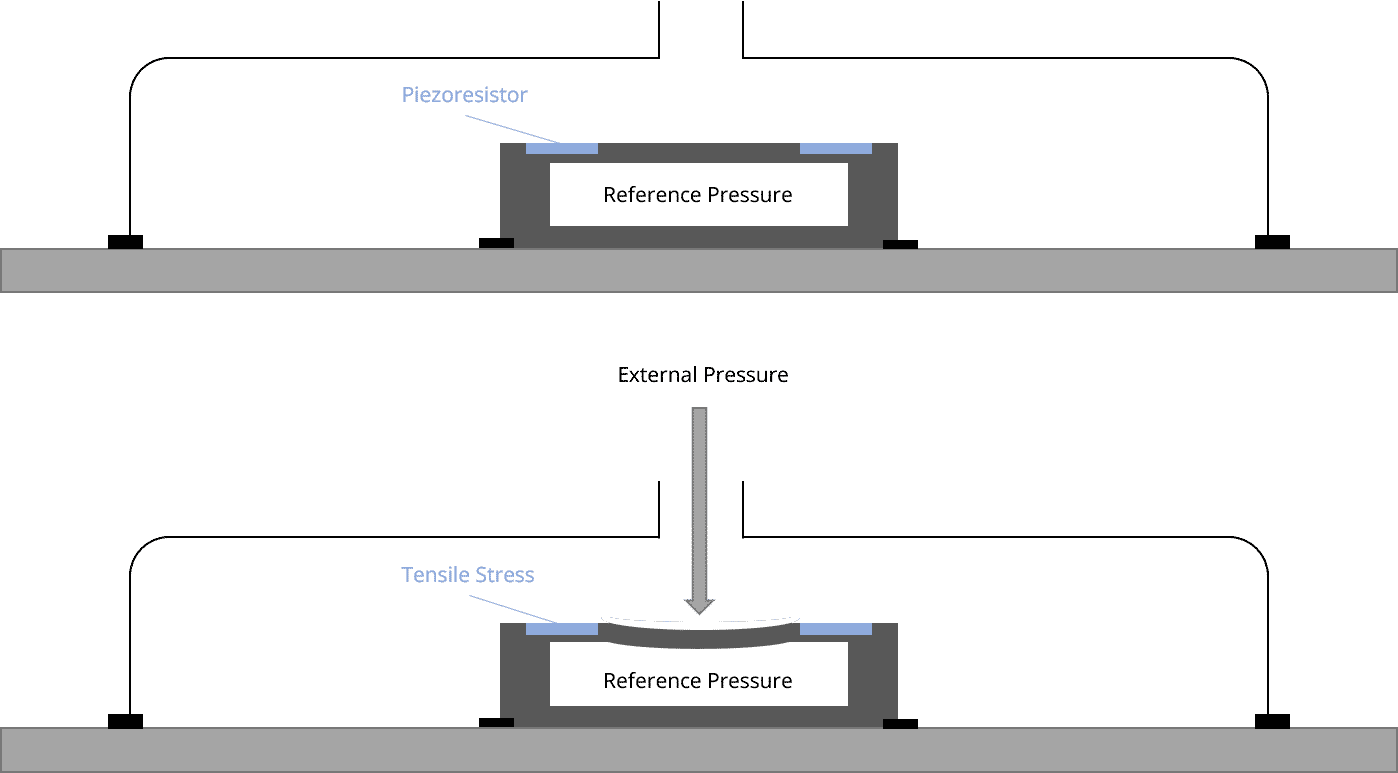

Capacitive Technology Measurement Principle

Two parallel and electrically isolated conducting plates are needed to ensure that a capacitive pressure sensor operates efficiently. The bottom plate is fixed while the top one is sensitive to pressure changes. When pressure is applied, the top plate (or membrane) bends and a capacitance Δ is created. This variation in capacitance is then translated to an electrical signal where it can be read and conditioned by an ASIC or microcontroller.

Technology Comparison, Piezoresistive Vs. Capacitive

In comparison to piezoresistive sensors, capacitive pressure sensors offer many advantages. Even though they may require more complex signal conditioning circuits and calibration algorithms, they have higher accuracy and lower total error band. Moreover, capacitive pressure sensors have low power consumption since there is no DC current flowing through the sensor element due to its nature. Thus, very low power sensing systems, can be designed and implemented that require only a small bias to the circuit by an external reader, making them ideal for remote or implanted medical applications. The table below summarizes the pros and cons of the MEMS capacitive pressure sensors with respect to the piezoresistive ones.

| Pros | Cons |

| Burst & proof pressure | Calibration complexity |

| Accuracy, total error band | Production cost |

| Power consumption | |

| Long term stability |

MEMS capacitive pressure sensors also offer excellent long-term stability. This is a design attribute. As illustrated above, a typical MEMS capacitive pressure sensor element features two sense and two reference capacitors. The reference capacitors are not sensitive to pressure variations. The pressure calculation is performed using the following algorithm.

Long term stability is mainly affected by the aging of the sensing elements and therefore the drift in measurement accuracy over time.

Due to the layout of capacitive dies, the sense and reference capacitors are exposed to the same environment. That means that they are exposed to the same conditions and stimuli that cause aging to the sensors and therefore long-term drift. Since the sense and reference capacitors are exposed to the same conditions and are manufactured using the same materials and procedures, they also age with the same rate. Therefore, utilizing the pressure calculation algorithm and the layout of the MEMS die, the long-term drift effect is minimized and therefore an excellent long-term stability is achieved.

Last but not least, the major advantage of MEMS capacitive technology over piezoresistive is the overpressure tolerance (proof pressure and burst pressure). Due to their design, MEMS capacitive sensors can withstand up to 100x the rated pressure. This happens due to the fact that the sensor architecture consists of a fixed bottom plate and a suspended membrane which deforms with pressure. When overpressure is applied the deformation reaches the bottom membrane and inevitably stops without breaking. At the same time due to the distance traveled and the stresses exerted there are no plastic deformations. This translates into an unaffected sensor performance after the release of the overpressure.

Is capacitive technology ideal for overpressure?

As explained above, whenever overpressure is applied to automation equipment, conventional pressure sensors could get damaged. For that reason, sensors based on silicon capacitive process technology could be used. Understanding the advantages of capacitive technology and the various ways it can be applied to pressure sensors is important and could lead to increased productivity and lower maintenance costs. ES Systems has designed pressure sensors with capacitive technology that can offer high performance and precision along with great efficiency and reliability at a competitive cost.

Are capacitive sensors ideal for medical applications?

Medical applications can be enhanced by MEMS capacitive pressure sensors, as they could provide very high accuracy and long-term stability. More specifically, they are extremely tolerant of overpressure, making them suitable for use in applications where measurement safety is critical and sensor repair is not an option.

The cutting-edge MEMS capacitive technology can be applied in demanding environments regarding absolute, gauge, relative, or differential pressure measurements. For this reason, ES Systems offers three families of high-end capacitive pressure sensors for those needing superior accuracy. These families are:

- ESCP-MIS1, designed to sustain high measurement quality in harsh environments and media. Available now.

- ESCP-BMS1, ideal for industrial, medical and HVAC applications that require high accuracy and low total error band. Available early December 2020.

|

|

| ESCP-MIS1 | ESCP-BMS1 |

Want to chat more about pressure sensors? Get in touch to tell us what you need!